Kohlenstoffabscheidung

Nikkiso hilft Kunden dabei, teures und verschwendetes CO2 -Emissionen in Gewinn umzuwandeln.

Individuelle, einfache, modulare und schlüsselfertige Dekarbonisierungslösungen – geeignet für Projekte jeder Größe.

Die Kohlendioxidanlagen von Nikkiso werden nach den Wünschen der Kunden konstruiert, hergestellt und installiert. einzigartige Bedürfnisse und Anforderungen. Wir können CO erfassen, reinigen, verflüssigen, speichern und transportieren2 der höchsten Reinheitsgrade. Anreize in Ländern auf der ganzen Welt fördern die Umsetzung von Dekarbonisierungslösungen in viele Branchen, darunter (aber nicht beschränkt auf) Lebensmittel und Getränke, Öl und Gas, Abfallwirtschaft, industrielle und chemische Verarbeitung sowie Pharmazie.

Kann die Dekarbonisierung aus mehreren Quellen unterstützen

- Thermische Stromerzeugung

- Erdgas-/RNG-Anlagen

- Bioabfallanlagen / Anaerobe Vergärungsanlagen

- Chemische Quellen

Was wir tun

- Beratung

- Projektmanagement

- Mit2 Anlagenplanung, -konstruktion und -bau

- Werkslieferung

- Vor-Ort-Montage, Inbetriebnahme und Start

- Ausbildung

- Service und Support

Wertversprechen

Warum Kunden zu Nikkiso kommen

- Bieten Sie die wirtschaftlichste Methode zur Erzeugung oder Rückgewinnung von lebensmitteltauglichem CO2.

- Für den vollautomatischen Betrieb konzipiert

- Erfordert minimale Betriebskosten

- In Containern verpackt und auf Paletten montiert, für eine einfache Installation und Inbetriebnahme vor Ort.

- Kundendienst wird angeboten

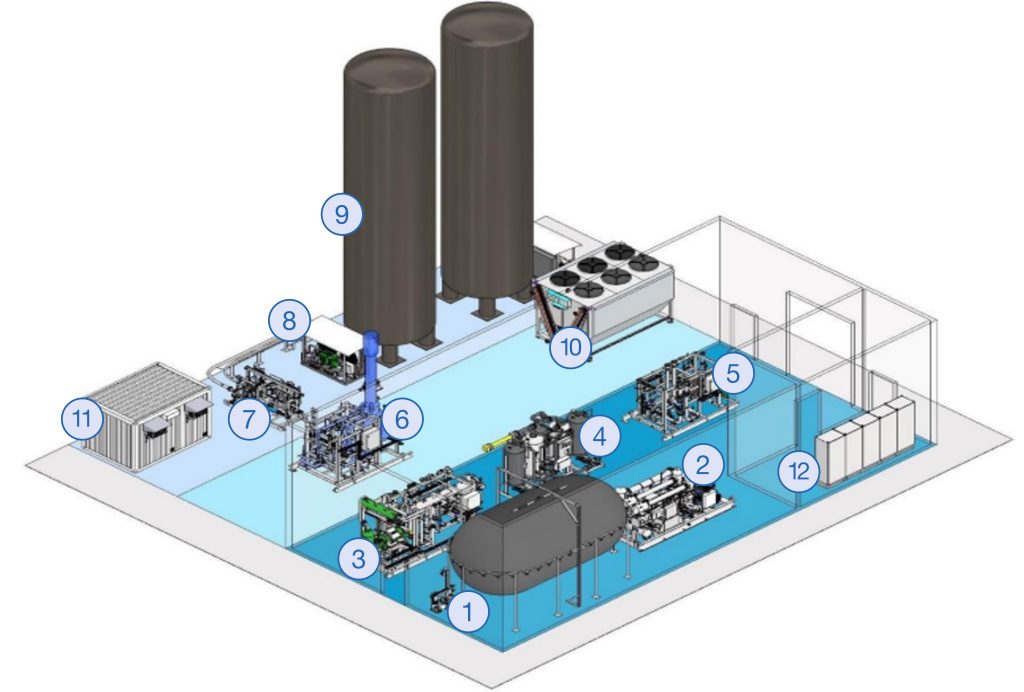

Ein typischer CO2 Anlagenlayout

- Gasballon / Pufferspeicher

- Mit2 Kompressor

- Mit2 Kondensator-/Kühlwasserpumpen-Skid

- Molekularsiebtrocknung und Aktivkohlefilter

- Kühlung (CO2 Kondensator)

- Mit2 Stripper / Reboiler / Feinreinigung

- LCO2 Transferpumpen (zum Beladen von LKWs)

- Servicekühlung (Tankkühlung)

- Vertikale Lagertanks

- Kühlturm

- LCO2 Gebäude für Getränkeanalysatoren

- Bedienfeld / MCC

Kennzahlen

- Anlagenleistungsbereich (der installierten Anlagen): 150 – 40.000 kg/Stunde

- Mehr als 3 Millionen Tonnen CO2 gefangen

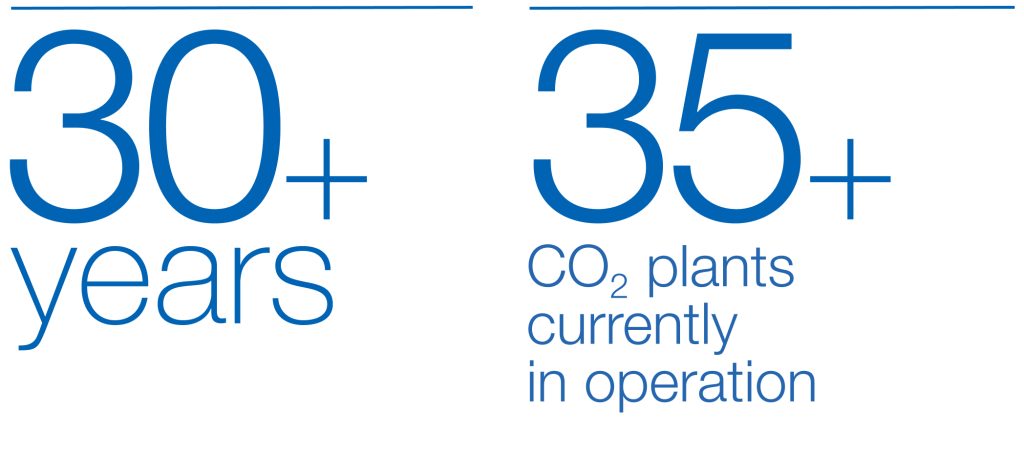

- 35+ CO2 Anlagen derzeit in Betrieb

- Unterstützt bis zu 6 Tonnen flüssiges CO2/Stunde

- 99,9% reines CO2 nach der Verarbeitung

- 30+ Jahre

Weitere News

x

Fragen Sie Nikkiso

Telefon: +1.951.677.2081

Email: info@nikkisoceig.com

„*“ zeigt erforderliche Felder an

Wir verwenden Cookies auf unserer Website, um Ihnen die relevanteste Erfahrung zu bieten, indem wir uns an Ihre Präferenzen erinnern und Besuche wiederholen. Indem Sie auf „Akzeptieren“ klicken, stimmen Sie der Verwendung ALLER Cookies zu. Lesen Sie hier mehr Cookie-Richtlinie.

Einwilligung verwalten

Notwendige Cookies sind für die ordnungsgemäße Funktion der Website unbedingt erforderlich. Diese Kategorie enthält nur Cookies, die grundlegende Funktionen und Sicherheitsmerkmale der Website gewährleisten. Diese Cookies speichern keine persönlichen Informationen.

Alle Cookies, die für die Funktion der Website möglicherweise nicht besonders erforderlich sind und speziell zum Sammeln personenbezogener Benutzerdaten über Analysen, Anzeigen und andere eingebettete Inhalte verwendet werden, werden als nicht erforderliche Cookies bezeichnet. Es ist obligatorisch, die Zustimmung des Benutzers einzuholen, bevor diese Cookies auf Ihrer Website ausgeführt werden.