BALSA - Hydrogen Liquefaction Plants

Hydrogen

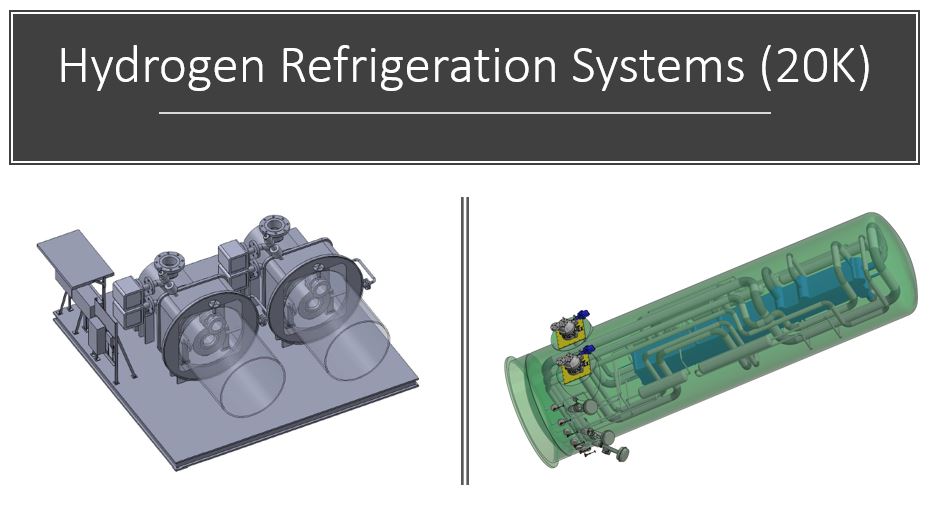

Cosmodyne Hydrogen Liquefiers

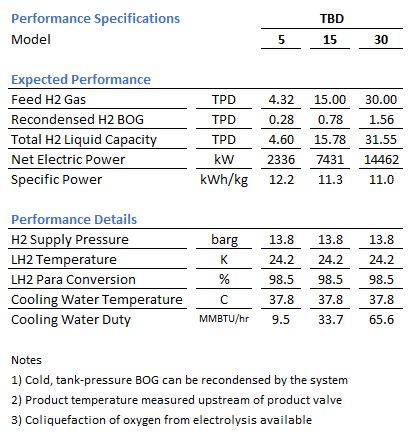

Hydrogen liquefaction is a key enabling technology for storing the lightest element on earth economically. As a liquid, this versatile energy carrier can be distributed efficiently. With over 60 years of cryogenic process plant experience and over 450 process plants successfully installed globally, Nikkiso Cosmodyne is pleased to launch the BALSA Series Hydrogen Liquefiers with three standardized sizes (5, 15 or 30 metric tons per day). Active Magnetic Bearings (AMB) eliminate oil systems and simplifies installation. The patent-pending liquefaction process is optimized for energy efficiency, ortho-para conversion reliability, and turndown flexibility. This modular, skid-mounted process plant is fabricated and assembled in-house by Nikkiso Cosmodyne’s global manufacturing facilities and configured to provide seamless integration with upstream hydrogen generation equipment and downstream storage and distribution facilities.

Features & Benefits

Nikkiso Cosmodyne’s BALSA Series Hydrogen Liquefier is a modular, skid-mounted system designed to treat and liquefy hydrogen for liquid hydrogen (LH2 ) production. The facility can be divided into four major sections:

- feed gas processing,

- hydrogen precooling and liquefaction,

- nitrogen refrigeration system

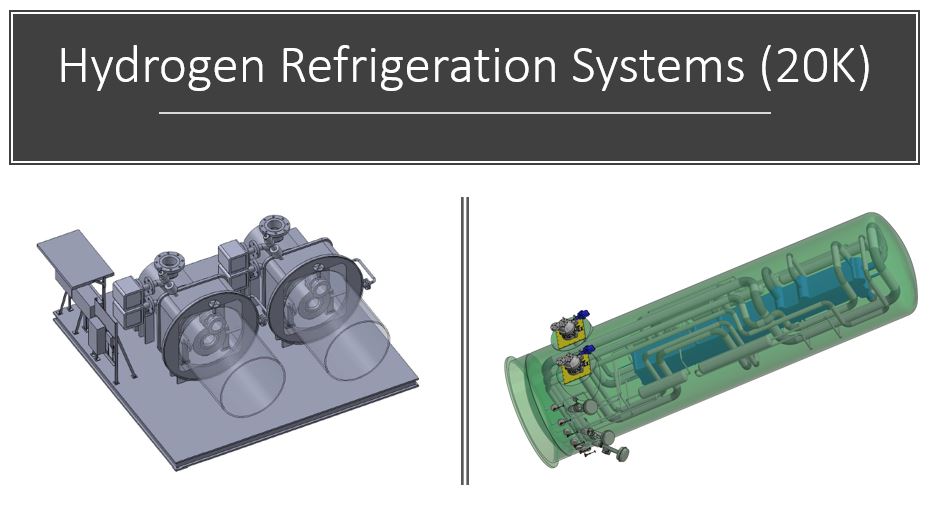

- hydrogen refrigeration system.

The feed gas processing section compresses the feedstock (optional) and removes any contaminants which would freeze in the nitrogen pre-cooling section. Once processed, the hydrogen may be safely admitted into the cryogenic system. In this section, the hydrogen is pre-cooled in an aluminum brazed heat exchanger with nitrogen. It is then liquified through another aluminum brazed heat exchanger against cooling hydrogen. While being liquefied, the hydrogen contacts a special catalyst to efficiently convert ortho to para hydrogen. Additionally, prior to entering the hydrogen cooling stage, the hydrogen product stream is treated again to remove any remaining contaminants that can freeze in the coldest section of the plant. The hydrogen liquid product is saturated at a temperature coincident with a client’s storage operating pressure. The Nikkiso Cosmodyne BALSA liquefier also fully integrates hydrogen flash gas recovery and may be operated to recover tank boil-off.

Specifications

- Over 60 years of cryogenic liquefaction design experience and over 450 cryogenic installations world-wide

- Pretreatment for different hydrogen feed stream sources

- Small footprint, modular system for economic shipping and installation

- Liquefaction systems from 5 to 30 mTPD

Cosmodyne_BALSA_V.1

Cosmodyne_BALSA_V.1 H2-Brochure_2022-JUL_6 - FINAL

H2-Brochure_2022-JUL_6 - FINAL